Last Change: 2026-01-28 #JT

Spherene V3: From Adaptive Geometry to Flow-Optimized Performance

Before diving into the latest features, a quick reminder of what makes Spherene different.

At the core of Spherene lies Adaptive Density Minimal Surfaces (ADMS) a patented geometry that continuously adapts its cell size and thickness across a part. ADMS supports smooth, continuous transitions without abrupt changes, enabling better mechanical control, surface conformity, and multifunctional performance.

In short:

-

Continuous density adaptation enables fine-grained control of mechanical response

-

Progressive, layer-by-layer failure avoids catastrophic collapse modes

-

Surface-conformal behavior allows ADMS to fit complex envelopes without sharp edges

-

Near-isotropic behavior, supports uniform performance under multi-directional loading

Building on this foundation, Spherene introduces a new generation of features designed to unlock controlled anisotropy and high-performance fluid applications.

New Feature 1: Scatter Vector - Introducing Controlled Anisotropy

ADMS is intrinsically close to isotropic by design. But real-world engineering problems are not always isotropic.

Scatter Vector gives users direct control over local geometric stretching through vector fields. Instead of uniform behavior in all directions, the geometry can now be intentionally biased.

How it works

-

Users define one or multiple vectors at various points across the volume

-

Vector direction determines where the geometry stretches

-

Vector magnitude (unit: mm) defines how much local stretching occurs

-

Two vectors per point enable multi-directional deformation

Applying scatter vectors allows ADMS to transition from near-isotropic to purposefully anisotropic behavior.

This feature enables:

-

Directional stiffness or compliance

-

Load-path-aligned structures

-

Local reinforcement without redesigning the envelope

Scatter Vector expands ADMS from a passive adaptive geometry into an actively guided structural system.

New Feature 2: Flow ADMS - Minimal Surfaces Optimized for Fluid Performance

While traditional ADMS and TPMS excel mechanically, fluid applications introduce two fundamental challenges:

-

Unbalanced labyrinths: the two internal chambers exhibit different flow resistances

-

High pressure drop: complex geometry causes excessive fluid resistance and pump energy demand

FlowADMS is a new geometry specifically designed to address these limitations.

What’s different about Flow ADMS

-

A newly developed, flow-inspired minimal surface

-

Optimized using energy-based algorithms

-

Designed to balance fluid resistances between both internal chambers

Despite its flow-oriented shape, Flow ADMS remains near-isotropic, maintaining the mechanical advantages of ADMS while radically improving fluid behavior.

The result

-

Nearly identical pressure drop in both chambers

-

Significantly reduced overall fluid resistance

-

Lower pump energy requirements

Flow ADMS enables ADMS-based designs to move confidently into heat exchangers, cooling systems, and other fluid-driven applications.

New Feature 3: Flow Direction -Defined Flow Paths

FlowADMS solves the baseline fluid challenges. FlowDirection takes optimization a step further.

This advanced feature allows users to define preferred flow paths via vector fields.

How it works

-

Users specify vectors at various points across the geometry

-

Vector direction defines the desired flow direction

-

Vector magnitude controls how strongly the surface aligns to the flow

The geometry automatically adapts to follow the prescribed flow paths, introducing intentional anisotropy for fluid performance.

Proven performance gains

In a heat exchanger comparison against a TPMS gyroid:

-

Flow Direction applied uniformly along one axis

-

Achieved greater than 20% lower pressure drop

-

Maintained equal thermal performance

With CFD-driven vector fields, even greater reductions in fluid resistance are expected.

Flow Direction transforms Flow ADMS from an optimized geometry into a design-driven flow system.

Beyond fluid applications, we are also looking forward to exploring how flow direction can introduce anisotropy into geometry, enabling better guidance of stress distribution and achieving longer lifetimes under mechanical loading.

Additional Improvements: Faster, Smarter, Safer Parametrization

Beyond new geometric capabilities, Spherene continues to improve everyday usability and reliability.

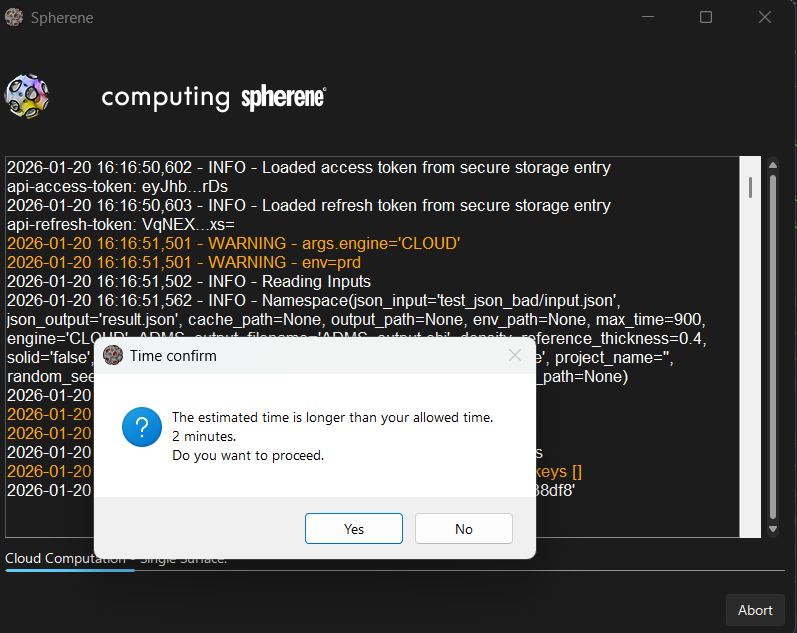

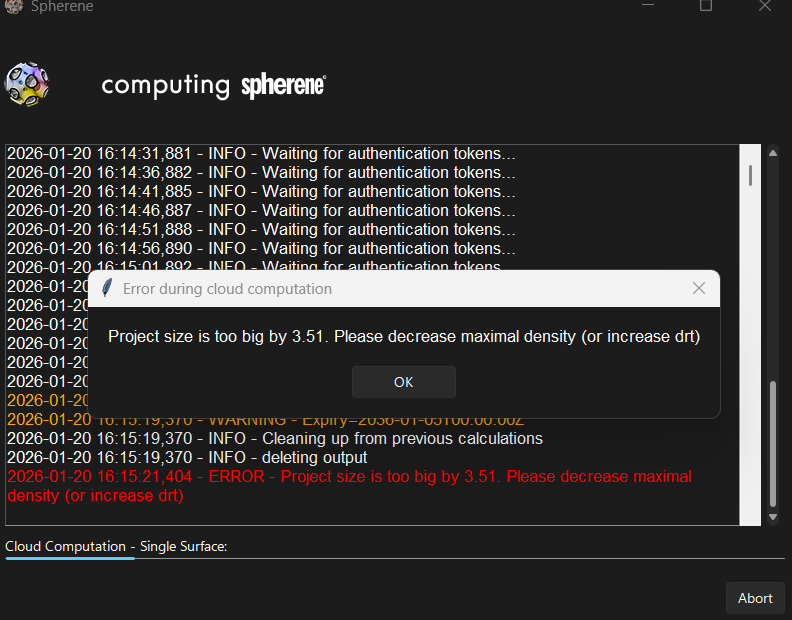

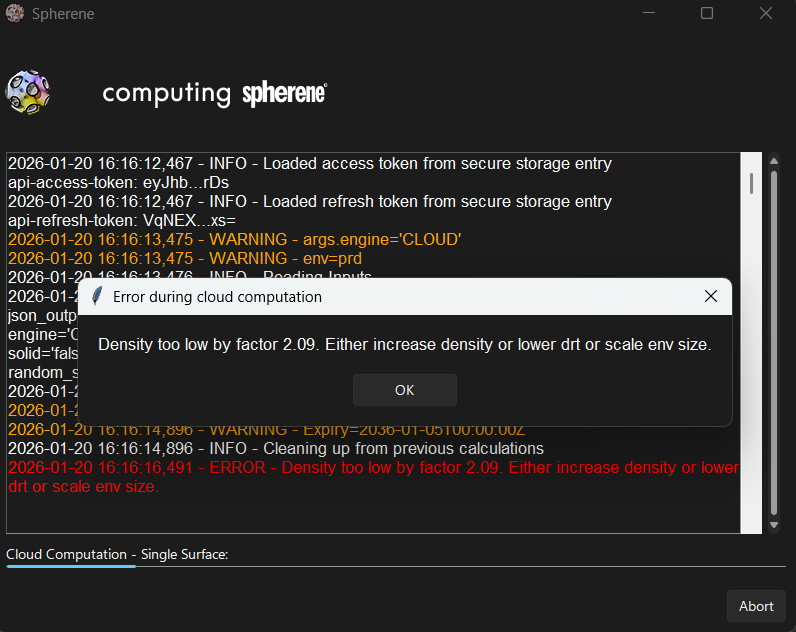

Improved guidance for realistic parametrization

-

Clearer feedback on parameter combinations that are physically or numerically unrealistic

-

Reduced trial-and-error during early design exploration

Faster error feedback

- Earlier detection of invalid inputs

- Immediate guidance to correct parametrization issues

These improvements help users reach valid, manufacturable designs faster, especially when working with advanced features like vectors and flow optimization.

Expanding Possibilities

With Scatter Vector, Flow ADMS, and Flow Direction, ADMS evolves beyond adaptive density into a platform for structural, thermal, and fluid optimization all within a single continuous geometry.

From lightweighting and energy absorption to high-efficiency heat exchange and flow control, Spherene continues to expand what minimal surfaces can do, without sacrificing mechanical integrity or design freedom.